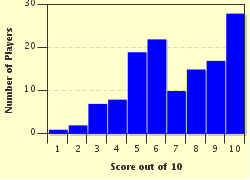

Quiz Answer Key and Fun Facts

1. You have decided to embark on the hobby of tumbling rocks or gemstones for jewelry that you would like to make. What type of store would you visit to learn about the hobby and buy equipment and supplies?

2. You have decided to purchase a rotary tumbler, as it is the most common type of tumbler for the beginner. It consists of a rotating barrel which uses water and an abrasive to shape and polish stones. When in use, what natural process does a rotary tumbler mimic to shape the material in the barrel?

3. You have placed your material inside of the tumbling barrel; you have added sufficient amounts of water and abrasive material as well. You place the barrel on the tumbler and watch it rotate slowly. Approximately how long will it take to complete the tumbling process of starting with rough material to obtaining a polished, final product?

4. You have loaded (charged) the barrel of the tumbler to begin the first stage in the process. How full should the barrel be with material to allow for adequate tumbling?

5. When selecting material to be placed within the tumbler, all of the material should be the same, as listed on the Mohs Scale. What does the Mohs Scale denote?

6. You have started the first grind of your material. During the first 72 hours, you should open the barrel every 24 hours to alleviate any buildup of pressure inside. During the first stage of the tumbling process, what causes the buildup of pressure within the barrel?

7. During all phases of tumbling the material, a slurry results which consists of abrasive and ground material. Where should you best discard the slurry when a tumbling phase is completed?

8. You have completed your first grind, which resulted in reducing the amount of material within the barrel, since the rocks have been rounded and reduced in size. Now, you have less material than what is optimal for proper tumbling. What is typically added to the barrel to get the material to fill to the proper amount?

9. The final step in processing the material is polishing it. And, you would need the appropriate abrasive to complete the process. How would you expect your polishing abrasive to be, in terms of coarseness, as opposed to the abrasives in the preceding steps?

10. While it is generally accepted that there are four tumbling steps in the process of achieving a finished product, there is actually a fifth optional step -- burnishing -- which can be used after the polishing step. Why is burnishing done?

Source: Author

ArsonDave

This quiz was reviewed by FunTrivia editor

ozzz2002 before going online.

Any errors found in FunTrivia content are routinely corrected through our feedback system.